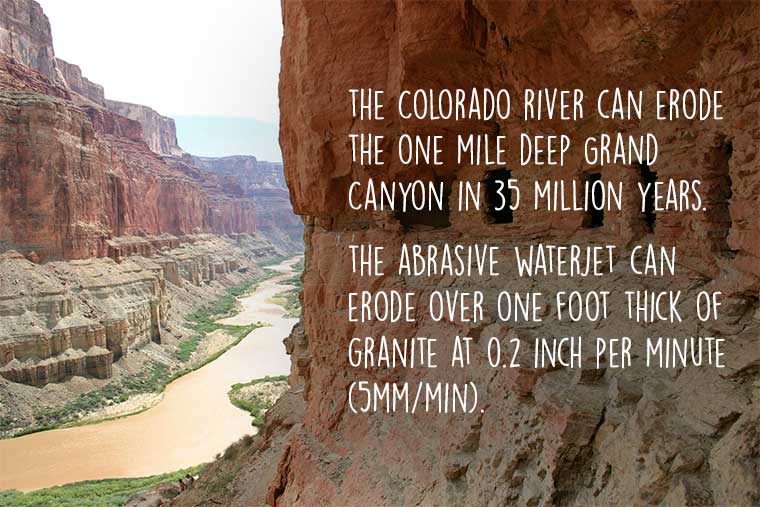

The Colorado River versus Waterjet

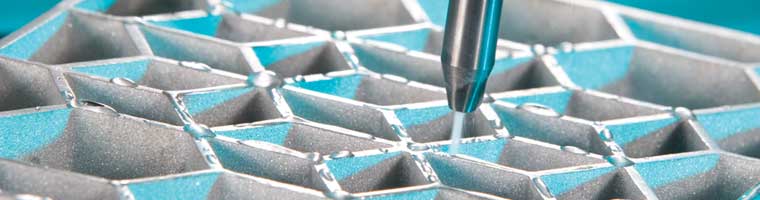

Waterjet gives the best edge. The surface is unaltered, exhibiting no heat or stress damage. This outstanding edge quality it is created by supersonic erosion.

Erosion is an extremely gentle form of material removal, however it achieves amazing results.

For example: the Colorado river can erode the one mile deep Grand Canyon in 35 million years, and the abrasive waterjet can erode over one foot thick of granite at 0.2 inch per minute (5mm/min).

Due to the gentle material removal, the edge that is exposed, be it canyon wall or granite or metal, is free of mechanical stresses (work hardening or warping) or heat affected zones (burned or melted in appearance and made harder and more brittle). In the Grand Canyon, for example, geologists can study Earth’s history through the nearly 40 layers of exposed rock as a result of gentle erosion. They can see every detail left behind dating back as far as 2 billion years (the Earth is only ~4.5 billion years old).

And in the manufacturing shop, we accelerate the erosion process with waterjet cutting. Manufacturing professionals benefit from a finished cut part that holds the original material properties. The material will perform in its’ final application the way it is supposed to. On the contrary, other cutting processes remove material much more violently, often changing the target material’s properties.

Cutting with plasma, oxy acetylene, or laser removes material by heat. The heat chemically and permanently changes the material; thus the material properties change. Heat can turn steel to martensite (very hard, very brittle material caused by rapid cooling after an elevated temperature, which is a real nemisis of fabricators and engineers). If a material is sheared apart (milling, turning, sawing, grinding), the material can also be changed. The edge can become work hardened, causing warpage and brittleness. Manufacturers utilize slow, gentle, and costly finish passes on mills, lathes, and grinders to try to remove the heat and stresses induced in a work piece.

On the contrary, our hero, the waterjet, is a cold cutting process that removes tiny amounts of material at supersonic rates. Shear forces remain small and localized. Removal rates are so fast that heat leaves with the tiny chips and grains rather than penetrate the edge left behind. With waterjet, stone won’t crack, glass won’t melt, plastic won’t deform, stainless won’t warp, etc. The best way to ensure you finish your cut with the same properties of the material you began with is to use waterjet.

Erosion is gentle, whether it occurs over millions of years or at supersonic rates, and has incredible cutting capability, as seen in abrasive waterjet cutting and the Grand Canyon.

Looking forward to your comments and blog suggestions.

chip

Nice post.Waterjet can cut any material with perfect shape and structure.Visit us for the best Waterjet Cutting

Water jet Cutting Services

LikeLike

Nice post.Waterjet can cut any type of material with perfect shape and structure.Visit us for best Waterjet cutting

Water jet Cutting Services

LikeLike