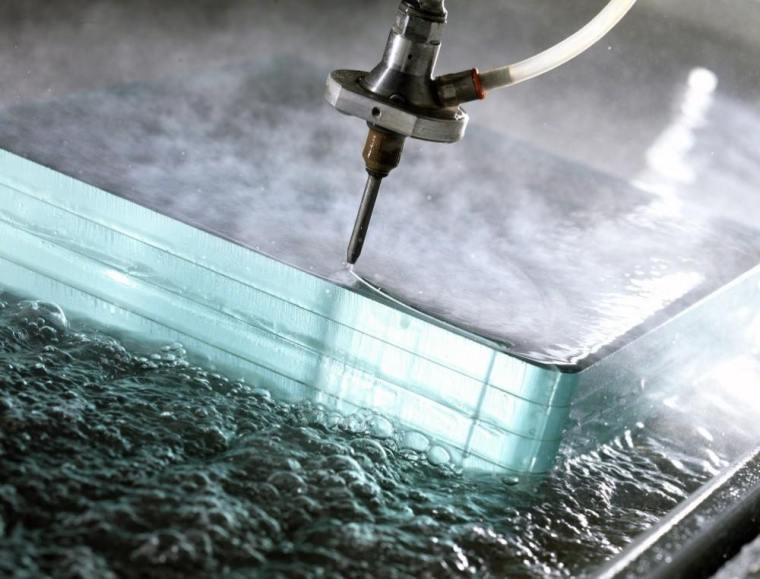

At first glance, nothing seems out of the ordinary as Gary Jamieson deftly operates the Flow Mach3-4020B with Dynamic Waterjet® on the factory floor at SBMC in Renfrewshire, Scotland. A second look, however, reveals that Gary is running the machine with one arm while standing on two prosthetic legs.

Gary, a disabled military veteran, was on patrol in Afghanistan in 2010 when his 1st Battalion Scots Guards found themselves in a minefield. Gary believes he stepped on the pressure plate of an IED (improvised explosive device) and when he turned, the device detonated. The resulting explosion took both Gary’s legs and his left arm. After leaving the military, Gary struggled to decide what to do next. He found his opportunity with SBMC.

“Gary is absolutely fantastic,” says SBMC Operations Manager Andy Russell. “He loves running the machine. He does the programming side of it and he’s learning every day.”

Hundreds of thousands of military personnel around the world like Gary have been awarded disability status as a result of wars in Iraq and Afghanistan. Many people, both in and out of government, talk about how they can help these brave veterans as they attempt to integrate into a civilian world. The Royal British Legion Industries (RBLI), the UK’s leading charity helping ex-Armed Forces personnel into employment, is actually doing something about it.

In 2018, RBLI established Scotland’s Bravest Manufacturing Company (SBMC) in an abandoned factory in the Erskine Veterans Village Estate in Bishopton, Renfrewshire. The commercially viable factory boasts state of the art technology and provides jobs and support to men and women adjusting to life outside the military.

“This is the first factory set up to get people proper skills and training as well as a bit of confidence and belief that they can get back into the working world,” says Andy. “Veterans who have spent time in the military, especially ones that have been damaged mentally or physically often struggle to get back into civilian life.”

Though in operation for just under a year, the operation is growing monthly and now has a staff of 14 employees and nine volunteers.

“The factory we’re in had been closed for six years and it was ideal for our purpose,” says Andy. “We were able to bring it back to life by updating everything – lighting, power, data lines. We had to put in the infrastructure before we could start.”

SBMC is now competing with commercial companies for sign manufacturing, fulfillment, and print and mail business.

“The Mach 3 Waterjet was the first machine in the factory,” says Andy, “and that was deliberate. We didn’t want to bring in bottom-rung jobs. I wanted something to aspire to. Working in my previous factory we purchased a waterjet cutter from Flow and it was the best thing since sliced bread. I felt we needed to get one here since it supports our core business of manufacturing road signs. More importantly, I felt the workers would be able to gain a huge amount of skill from the advanced technology and something they could take to other jobs. Flow has been extremely supportive, and the waterjet is now a central part of the factory.”

In addition to the sign making operation, SBMC is starting to get subcontracting business for the waterjet.

“Companies around here are getting components made elsewhere normally through plasma cutting or machining,” says Andy. “One of our customers needed parts that had to be punched out, but they were getting distortion and scrap using conventional machining. They came to us to have the parts cut with the waterjet. We want to continue to grow that business and become a supplier to local companies who need that kind of work.”

Andy says the flexibility of the waterjet is particularly attractive and people in the area are continually surprised by the ability to cut with water. He says they have been cutting a wide variety of material with the waterjet including metal and granite.

“The machine is very simple to operate if you follow the basics,” says Andy. “The guys are getting a handle on it and are getting good at problem-solving. The machine itself is robust, simple, and accurate. It does what we ask it to do on a daily basis. We have had the machine since last July and have had no issues with it. It’s one less thing we have to worry about.”

Andy stresses that the company’s goal is about more than just training the operators to run a waterjet.

“We’re here to help and support them, and if they thought they had no chance of a career, we show them that they do,” says Andy. “The waterjet is a great part of that jigsaw. If we give them the confidence that they can do whatever they want, then we’ve done our job.”

This is a great idea! I’ll bet there are a lot of vets out there who can offer a whole lot. Just reading this I was thinking that injured veterans would be really, really good at helping to retrain injured pets or to work with pet owners who probably have more trouble getting used to a dog or cat losing a leg. Well done, guys.

LikeLike